iV-500

- Spindle material is SCM415 full hardened through carbonizing heat treatment

- NST#30/R8 spindle with 3HP variable speed motor (inverter motor option is available).

- Spindle quill drive box is transmitted by ballscrew for better precision.

- Essential castings are made of high grade of Meehanite cast iron, which has been stressed and relieved to provide a rigid machine structure.

- Standard with 10” X 54” table with hardened and ground.

- Table T-slot is precision ground to exact tolerance.

- Precision ballscrews are equipped on X&Y axes.

- X and Y slideways and gibs are coated with Turcite-B to provide smooth and wear resistant surface.

- 1:2 ratio timing belt pulleys on XY axes to increase drive torque.

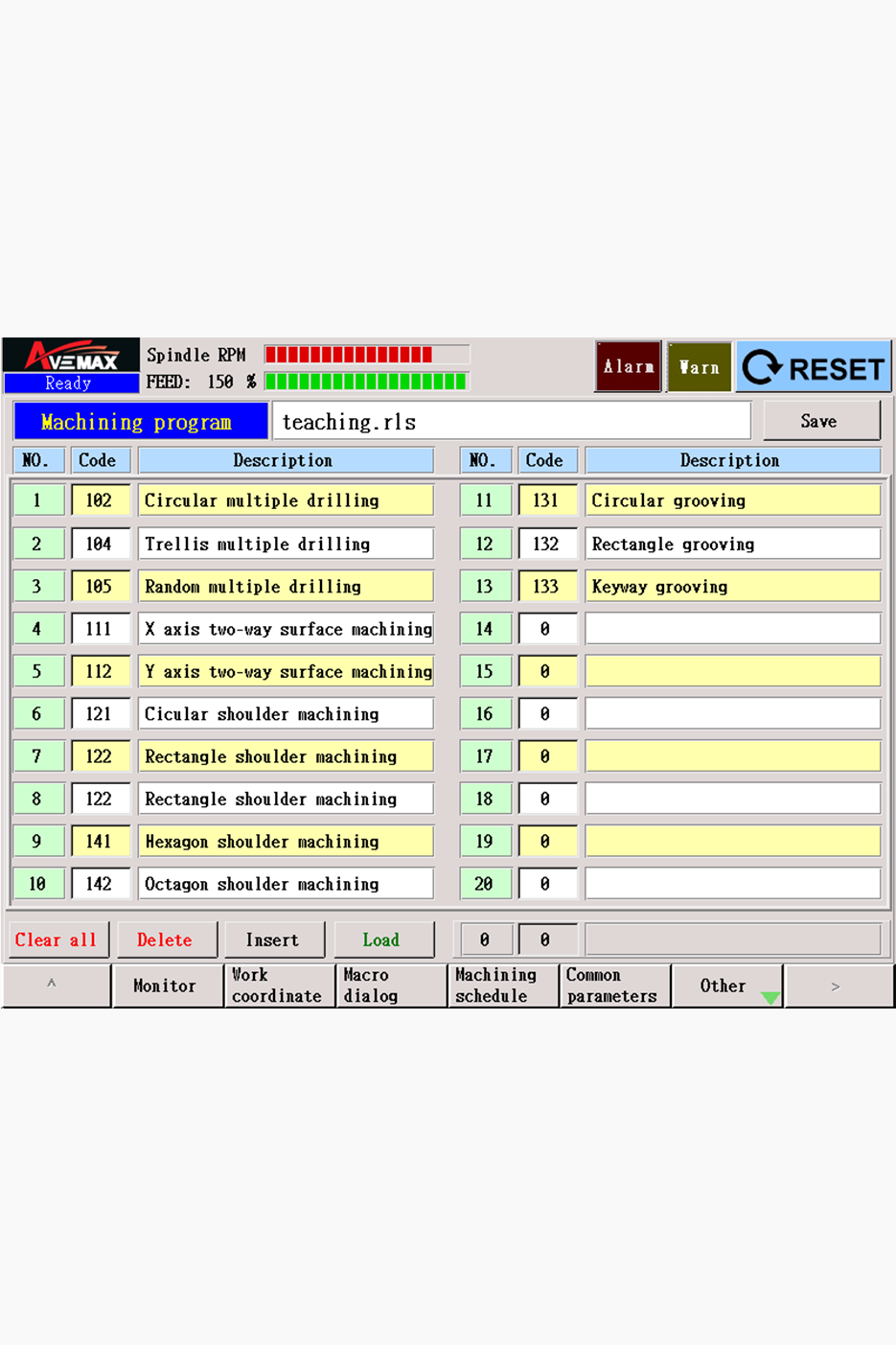

iPRO Intelligent Conversational Control System |

Features

|

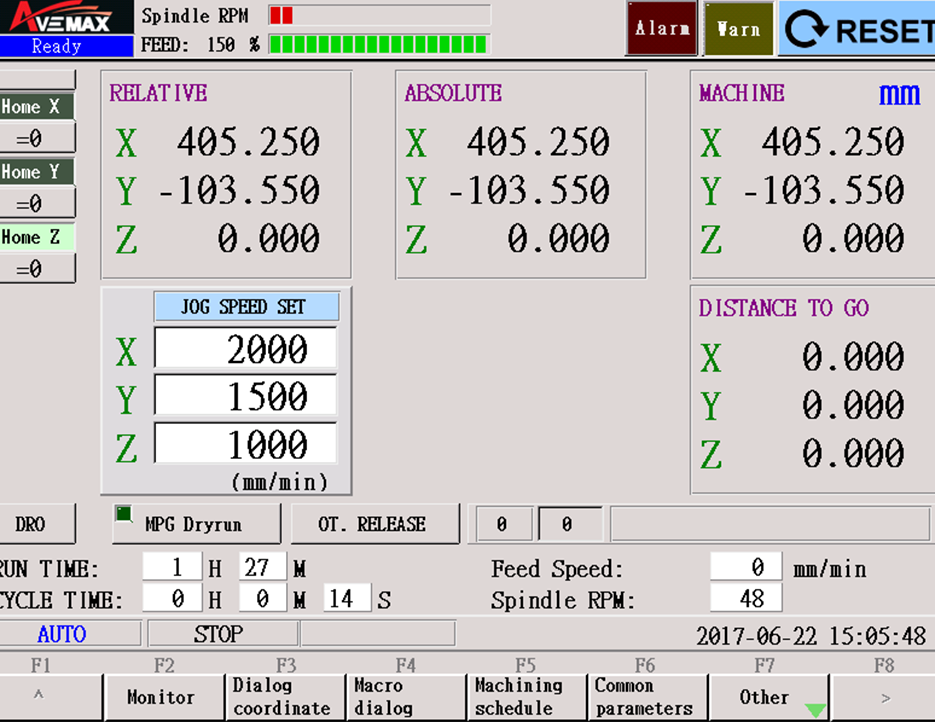

DRO mode

|

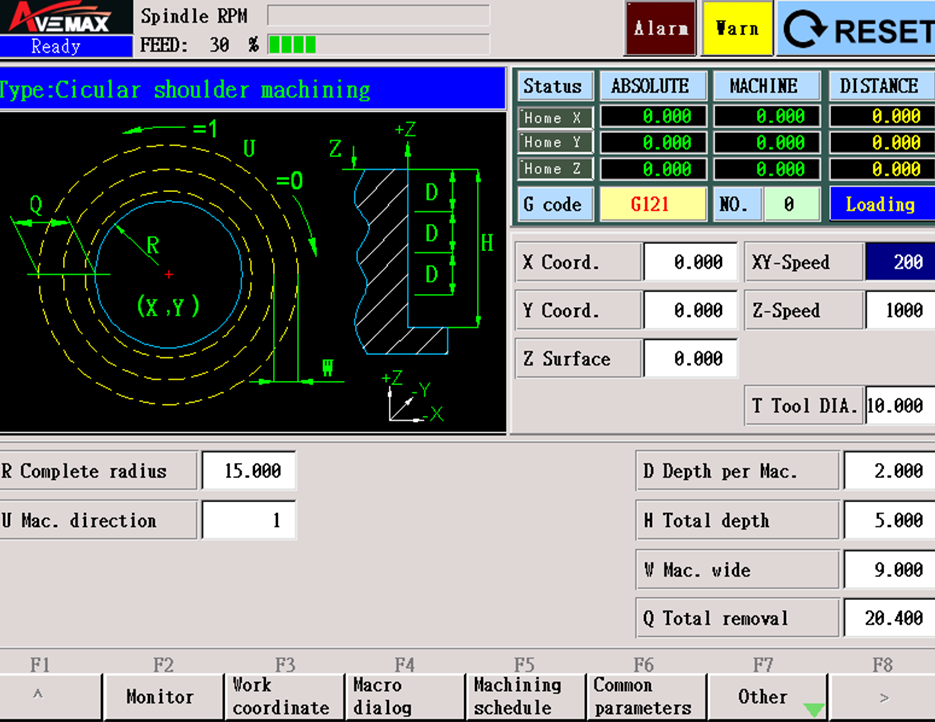

Programming

Program Storage

|

Help pages

Learning

Task scheduling

|

CAD/CAM input

|

| Specification | iV-500 | |

| Travel | ||

| X/Y/Z travel | Manual way: 700/370/440mm (28"/15"/17") | |

| Spindle nose to table surface | 85~535mm (3.3"~21") | |

| Spindle center to column surface | 170~730mm (6.7"-28.7") | |

| Ram travel | 560mm (22") | |

| Table | ||

| Table size | 1372 x 254mm (54" x 10") | |

| Table T-slot (No. x size) | 3 x 16mm (3 x 0.63") | |

| Max. table load | 350kgs (771 Lbs) | |

| Spindle | ||

| Spindle taper | NST#30/R8 | |

| Spindle speed | 5000rpm | |

| Quill feed | 0.04mm~0.08mm~0.14mm (0.0015"~0.003"~0.006") | |

| Transmission | Variable speed (Opt. inverter) | |

| Quill travel | Manual way: 110mm (4.3") | |

| Over swivel on turret | 360゜ | |

| Head swivel (R&L) | +/-45゜ | |

| Head swivel (Up & down) | +/-45゜ | |

| XY feed rate | 0~3M/min (0-0.12") | |

| Rapid feed rate XYZ | 5M/min (0.2"/min) | |

| Motor | ||

| Spindle motor | 3HP inverter motor | |

| XYZ motor | 1Kw AC servo motor | |

| XYZ transmission | 1:2 Belt | |

| Coolant pump | 1/8HP | |

| Machine size | ||

| Overall width (A) | 2580mm (102") | |

| Overall depth (B) | 2080mm (82") | |

| Overall height (C) | 2310mm (91") | |

| Net weight | 1700kgs (3,747 Lbs) | |

We reserve the right to modify and improve the specification without notice. The specification shown above is for reference only.