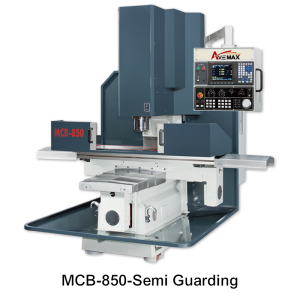

MCB-850

- VMC rigid headstock moves directly on column without extra bracket to ensure heavy cutting accuracy.

- BT40 spindle is fully balanced for low chatter and high performance machining.

- All essential castings are made of high grade of Meehanite cast iron, which has been stressed and relieved to provide a rigid machine structure.

- All three axes are driven by high precision ballscrews with double nuts which leads less play and backlash.

- Dovetail design on X, box way design on YZ.

- All slideways have been hardened and ground for longer longevity. It also provides high rigidity for heavy and discontinuously cutting.

- All contacting surfaces are precisely hand scrapped.

- YZ slideways are protected by high grade steel covers.

- 1:2 ratio timing belt pulleys on XYZ axes to increase drive torque and save the cost of axes motors.

| Specification | MCB-850 |

| Table size | 1270 x 305mm |

| T slot of spindle (number x width) | 3 x 16mm |

| Longitudinal travel | 850mm |

| Cross travel | 450mm |

| Vertical travel | 450mm |

| Table load capacity | 400Kgs |

| Spindle taper | BT40 |

| Spindle speed | 8000rpm |

| Spindle motor | 7.5HP |

| Spindle nose to table surface | 150-600mm |

| Spindle center to column front surface | 510mm |

| Cutting feed rate | 0~10M/min |

| Rapid feed of XYZ axes | 12M/min |

| coolant pump | 1/6HP |

| Length x Width x Height | 2960 x 1975 x 2515mm |

| Net weight | 2100Kgs |

We reserve the right to modify and improve the specification without notice. The specification shown above is for reference only.